Electrical Maintenance: Ensuring Safety and Efficiency

Electrical maintenance is a critical aspect of keeping any residential, commercial, or industrial facility safe and operational. Proper maintenance not only ensures the longevity of electrical systems but also plays a significant role in preventing accidents, enhancing energy efficiency, and reducing operational costs. Regular upkeep of electrical components, systems, and infrastructure is necessary to avoid unexpected failures that can lead to significant downtime or even catastrophic events like fires or electrical shocks.

Importance of Electrical Maintenance

One of the primary reasons for regular electrical maintenance is safety. Electrical systems are complex and can pose serious risks if not properly maintained. Faulty wiring, outdated components, and neglected systems can result in electrical fires, equipment damage, or even personal injury. By conducting regular inspections and maintenance, potential hazards can be identified and rectified before they escalate into serious problems.

Another critical aspect of electrical maintenance is ensuring energy efficiency. Over time, electrical components can wear out, leading to increased resistance in the circuits. This can cause the system to consume more power than necessary, leading to higher energy bills. Regular maintenance helps in identifying and replacing such worn-out components, ensuring that the system operates at its optimal efficiency.

Types of Electrical Maintenance

Electrical maintenance can be broadly categorized into three types: preventive, predictive, and corrective maintenance.

-

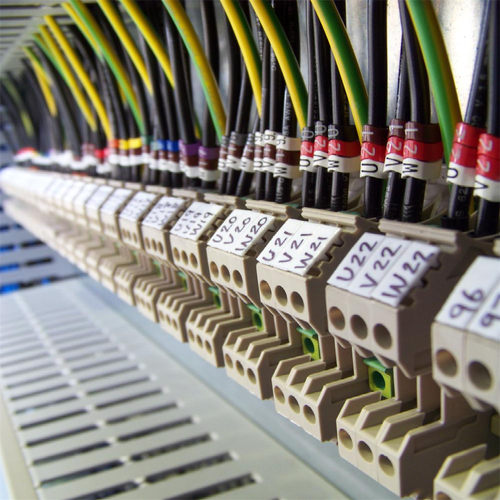

Preventive Maintenance: This type of maintenance involves regular inspections and servicing of electrical systems to prevent potential issues before they occur. Activities may include testing circuit breakers, inspecting wiring, cleaning components, and tightening connections. Preventive maintenance is typically scheduled at regular intervals, depending on the system's complexity and operational demands.

-

Predictive Maintenance: This approach utilizes advanced monitoring tools and techniques to predict when a component is likely to fail. By analyzing data such as temperature, vibration, and electrical load, maintenance teams can identify signs of wear or degradation in advance. Predictive maintenance allows for more targeted interventions, reducing the likelihood of unexpected breakdowns and extending the lifespan of electrical components.

-

Corrective Maintenance: When an electrical system fails or malfunctions, corrective maintenance is required to repair or replace the faulty components. While this type of maintenance is reactive, it is an essential part of any comprehensive maintenance strategy. Quick response to electrical failures is crucial to minimize downtime and restore normal operations.

Best Practices for Effective Electrical Maintenance

-

Regular Inspections: Schedule regular inspections to assess the condition of electrical systems. This includes checking wiring, circuit breakers, switches, outlets, and any other components that are part of the electrical infrastructure.

-

Use of Quality Components: Ensure that only high-quality components and materials are used for repairs and replacements. Substandard parts can lead to frequent failures and pose safety risks.

-

Documentation: Maintain detailed records of all maintenance activities, including inspections, repairs, and replacements. This documentation can help track the system's history and identify recurring issues that may require a more comprehensive solution.

-

Training and Awareness: Ensure that maintenance personnel are well-trained and up-to-date with the latest safety standards and technologies. Additionally, educate building occupants about basic electrical safety practices to prevent accidents.

-

Compliance with Standards: Adhere to local and national electrical codes and standards. Compliance not only ensures safety but also avoids legal complications.

Conclusion

Regular electrical maintenance is vital for the safety, efficiency, and reliability of electrical systems. By implementing a well-structured maintenance plan that includes preventive, predictive, and corrective measures, facilities can significantly reduce the risk of electrical failures, lower energy costs, and extend the lifespan of their electrical infrastructure. Prioritizing electrical maintenance ultimately leads to safer environments, smoother operations, and cost savings in the long run.